ADVERTISEMENTS:

Relative density of cohesionless soils is defined as the ratio of the difference between the void ratio of a cohesion- less soil in the loosest state and in-situ void ratio to the difference between its void ratios in the loosest and the densest states. Thus relative density (Dr), also called density index (Id), is defined by –

Dr = [(emax – e)/(emax – emin)] x 100 …(4.80)

where emax is the maximum void ratio of soil corresponding to the loosest state, e is the in-situ void ratio, and emin is the minimum void ratio of soil corresponding to the densest state.

ADVERTISEMENTS:

Relative density is also called density index and both the terms are used as replaceable terms with each other. The concept of relative density gives a practically useful measure of compactness of cohesionless soils in a natural or artificially compacted state. Various soil properties, such as penetration resistance, compressibility, friction angle, permeability and California bearing ratio, are found to have simple relationships with relative density.

Relative density, therefore, gives a better indication of the strength and deformation of soil than its void ratio or density. Two sands having same relative density would show similar behavior under loads, although their void ratios may be different.

Relative Density in Terms of Density:

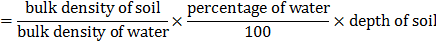

To determine the relative density, it is necessary to determine the specific gravity of soils in order to calculate the void ratio from dry density in the loosest, in-situ, and densest states. It is useful to express relative density directly in terms of dry density in loosest, in-situ, and densest states, so that the need to determine the specific gravity of soil is eliminated. We know that the in-situ void ratio of soil is given by the relation–

e = Gγw/γd – 1

ADVERTISEMENTS:

Similarly, the maximum and minimum void ratio of soil corresponding to loosest and densest states are given, respectively, by –

emax = (Gγw/γd min) – 1 …(4.81)

emin = (Gγw/γd max) – 1 …(4.82)

Substituting these values in Eq. (4.80), we obtain the expression for relative density as –

Equation (4.75) is commonly used to determine the relative density of soil in the laboratory.

Determination of Relative Density:

Relative density of a natural cohesionless or compacted soil can be determined in the laboratory by using the standard relative density equipment.

Principle:

The relative density of natural or compacted soil can be determined by obtaining the minimum and maximum density of soil in the laboratory and the in-situ density of soil in the field. The test is applicable for freely draining cohesionless soils only.

The minimum density in the loosest state is obtained by pouring the soil sample into the mold from a standard height of 25 mm. The maximum density in densest state is obtained by applying vibrations to the mold with soil on a vibrating table. The in-situ density of soil is obtained in the field using sand replacement method or any other suitable method.

Equipment:

ADVERTISEMENTS:

Typical equipment used for the determination of relative density.

A typical relative density apparatus consists of the following components:

i. Vibratory table, a steel table with a cushioned vibrating deck about 75 cm × 75 cm of size, consisting of a vibrator with a net mass of over 45 kg and frequency of 3600 vibrations per minute.

ii. Cylindrical metal unit mass molds of 3000 and 15000 cm3 capacity with guide sleeves.

ADVERTISEMENTS:

iii. Surcharge base plates with handle – one surcharge base plate, 10 mm in thickness, for each size mold.

iv. Surcharge masses – one surcharge mass for each size mold.

v. Calibration bar of metal and 75 x 300 x 3 mm in size.

vi. Dial gauge holder.

vii. Dial gauge – 50 mm travel with 0.025 mm graduations.

viii. Balance – portable platform scale, 100 kg capacity with sensitivity of 20 g.

ix. Micrometer.

x. Stop watch.

xi. Metal straight edge – about 40-cm long.

Procedure:

The procedure for the determination of relative density, as recommended by IS – 2720 (Part 14) – 1983, is given as follows:

1. Selection of Cylindrical Mold:

The cylindrical mold of suitable size is selected. For soils with maximum particle size less than 75 mm, the smaller mold of 3000 cm3 capacity is used. If the maximum particle size is 75 mm, the larger mold of 15000 cm3 is used.

2. Determination of Volume of the Mold:

The volume of the mold should be determined by direct measurement and checked by filling with water. The initial dial reading for computing the volume of the specimen should be determined.

i. By Direct Measurement:

The average inside diameter and height of the mold are measured. Volume of the mold is calculated. The average inside cross-sectional area of the mold is also calculated.

ii. By Filling with Water:

The mold is filled with water and a glass plate should be slid carefully over the top surface of the mold in such a manner as to ensure that the mold is completely filled with water. The mass of the water filling the mold is determined. The volume of the mold is calculated by dividing the mass of water with the density of water.

3. Preparation of Soil Sample:

A representative sample of soil of 12 kg mass is taken if the maximum size of the soil particle is less than 75 mm. However, if the maximum size of the soil particle is 75 mm, 45 kg of the sample should be used for the test. The soil sample is dried in an oven at a temperature of 105°C to 110°C. The soil sample is then pulverized without breaking the individual soil particles and sieved through the required sieve.

4. Determination of the Volume of the Specimen:

The volume of the specimen in the loosest state (Vc) is determined in the following steps:

i. The thickness of the surcharge base plate and the calibration bar are measured to the nearest 0.025 mm using a micrometer. The dial gauge holder is inserted in each of the guide brackets of the mold.

ii. Six dial gauge readings should be obtained, three on one side and three on the other, and the average of the six readings is taken. The initial dial reading should be computed by adding together the surcharge base plate thickness and the average of the six dial gauge readings and subtracting the thickness of the calibration bar. The initial dial reading is constant for a particular mold and surcharge base plate combination.

5. Determination of Minimum Density:

This is done in the following steps:

i. The mold should be weighed and the mass recorded. Soil should be placed as loosely as possible in the mold by pouring the soil through the spout in a steady stream with a constant height of free fall of the soil of 25 mm.

ii. While pouring the soil, the pouring device should be moved in a spiral motion from the outside toward the center to form a soil layer of uniform thickness without segregation. The mold should be filled approximately 25 mm above the top and levelled with top by making one continuous pass with the steel straightedge. If all excess matter is not removed, an additional continuous pass should be made. The mold and the soil should be weighed and the mass recorded.

6. Determination of Maximum Density:

The maximum density may be determined by either the dry or wet method. While the dry method is preferred from the standpoint of securing results in a shorter period of time, the highest maximum density is obtained from some soils in a saturated state. The maximum density test should be performed on both wet and dry soils to determine which method results in higher maximum density. If the wet method produces higher maximum densities (in excess of one percent), it shall be followed in succeeding tests.

(a) Dry Method:

The dry method for determination of maximum density consists of the following steps:

(i) The mold should be filled with thoroughly mixed oven-dry soil. The guide sleeves should be attached to the mold and the surcharge base plate should be placed on the soil surface. The surcharge weight should then be lowered on the base plate using the hoist in the case of the 15000 cm3 mold.

(ii) The mold should be fixed to the vibrator deck for assembly and the loaded soil specimen should be vibrated for 8 min.

(iii) The surcharge weight and guide sleeves should be removed from the mold. The dial gauge readings on two opposite sides of the surcharge base plate should be obtained and the average recorded. The mold with the soil should be weighed and its mass recorded.

(b) Wet Method:

The wet method may be conducted on dry soil or wet soil from the field.

The wet method for determination of maximum density consists of the following steps:

(i) The mold should be filled with wet soil. Sufficient water should be added to the soil to allow a small quantity of free water to accumulate on the surface of the soil during filling. During and just after filling the mold, it should be vibrated for a total of 6 min. During this period, the amplitude of the vibrator should be reduced as much as necessary to avoid excessive boiling and fluffing of the soil, which may occur in some soils. During the final minutes of vibration, any water appearing above the surface of the soil should be removed.

(ii) The guide sleeve, surcharge base plate and surcharge weight should be assembled as described in step [6 (a) (i)] above.

(iii) The specimen with the surcharge weight should be vibrated for 8 min. After the vibration, the surcharge weight and the guide sleeve should be removed from the mold. Dial gauge readings should be obtained on two opposite sides of the surcharge base plate and recorded. The entire wet specimen should be carefully removed from the mold, dried to constant mass, weighed and the mass recorded.

7. Determination of In-Situ Density:

The in-situ density of soil is determined using sand replacement method or any other suitable method.

Calculations:

i. Minimum Density:

The minimum density, γd min, is calculated as –

γd min =Wsm/Vc …(4.84)

where Wsm is the mass of dry soil in the minimum density test in g and Vc is the calibrated volume of the mold in cm3.

ii. Maximum Density:

The maximum density, γd max, is calculated as –

γd max = Ws/ Vs …(4.85)

where Ws is the mass of dry soil in the maximum density test in g, Vs is the volume of soil in the maximum density test in cm3 given by –

Vs = Vc – [A×(Di – Df )] …(4.86)

where A is the cross-sectional area of the mold in cm2, Di is the average initial dial reading in cm, and Df is the average final dial reading in cm.

The relative density is calculated using Eq. (4.83)

Soil Classification Based on Relative Density:

The state of compactness of soil is classified on the basis of relative density as shown in Table 4.4.

Comments are closed.