ADVERTISEMENTS:

The following are the various types of retaining walls: 1. Gravity Walls 2. Semi-Gravity Retaining Walls 3. Cantilever Retaining Walls 4. Counterfort Retaining Walls 5. Buttressed Retaining Walls 6. Sheet Piles 7. Miscellaneous Types of Retaining Structures.

Type # 1. Gravity Walls:

Gravity walls derive their lateral stability by their mass. Gravity retaining walls are designed to resist earth pressure by their weight. They are constructed of the mass concrete, brick, or stone masonry. Since these materials cannot resist appreciable tension, the design aims at preventing tension in the wall.

Some gravity walls do not use mortar, relying solely on their weight to stay in place, as in the case of dry stone walls. These walls generally are trapezoidal in section as shown in Fig. 16.2. Gravity walls require heavy foundation due to the large size of the wall. They are economical and suitable for only small heights.

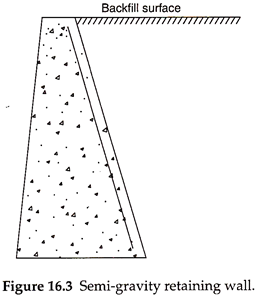

Type # 2. Semi-Gravity Retaining Wall:

A gravity retaining wall provided with a small amount of reinforcement for reducing the mass of the concrete is known as semi-gravity retaining wall, as shown in Fig. 16.3. The lateral earth pressure is principally resisted by the mass of the wall, as in the case of a gravity retaining wall.

Type # 3. Cantilever Retaining Wall:

These are the reinforced concrete walls in which lateral earth pressure is resisted by structural action of its members. The base of the wall is extended into the backfill on the heel side and is known as heel slab, as shown in Fig. 16.4. The backfill over the heel slab provides significant additional lateral stability to the wall. The back of the wall on the heel side is also given a slope. This increases the width of the wall with depth, similar to the increase in lateral earth pressure with depth.

The vertical wall (known as stem), the heel slab, and the toe slab act as cantilevers fixed at their junction and spanning to the other end. The stem is subjected to lateral earth pressure, causing bending away from the backfill. The heel slab and the toe slab are subjected to resultant upward soil pressure from the bottom and bend upward. Reinforcement is therefore provided on the tension side, that is, vertically on the backside of the stem and horizontally at the bottom of the heel slab and the toe slab.

The weight of a cantilever retaining wall is significantly less than that of a gravity retaining wall and therefore requires only lighter foundations.

Cantilever retaining walls are suitable for retaining the backfill to moderate heights of 4-7 m. In cross section, most cantilevered walls look like “L”s or inverted “T”s. Where foundation soils are poor, earth tieback retaining walls are another choice. These walls are counterbalanced not only by a large base but also by a series of horizontal bars or strips extending out from the vertical surface into the backfill. The bars or strips, sometimes called “dead- men” are made of wood, metal, or synthetic materials, such as geotextiles. Once an earth tieback retaining wall is backfilled, the weight and friction of the fill against the horizontal members anchors the structure.

Type # 4. Counterfort Retaining Wall:

When the height of a cantilever retaining wall is more than about 7 m, it is economical to provide a vertical bracing system, known as counterforts, on the backfill side above the heel slab. The counterforts are triangular beams of variable depth and uniform width, connecting the heel slab and the stem, provided at a regular spacing along the length of the wall, as shown in Fig. 16.5.

The stem and the heel slab act as continuous slabs spanning horizontally along the length of the wall between the counterforts. The use of counterforts reduces the bending moment due to earth pressure and hence the size and reinforcement of the stem and the heel slab. Counterforts are subjected to tension due to the action of lateral earth pressure of the backfill on the stem.

Type # 5. Buttressed Retaining Walls:

When the triangular beams are placed on the front side of the retaining wall, instead of on the backfill side under certain situations, the retaining wall is known as buttressed retaining wall, and the triangular beams are known as buttresses, instead of counterforts. Figure 16.6 shows a buttressed retaining wall. The structural action of the stem is the same as in a counterfort retaining wall.

However, the heel slab acts as a cantilever slab as in a cantilever retaining wall. The toe slab acts as a continuous slab spanning along the length of the wall between the buttresses. Buttresses are subjected to compression due to lateral earth pressure of the backfill on the stem and that due to upward soil pressure on the toe slab.

Type # 6. Sheet Piles:

ADVERTISEMENTS:

Sheet piles are flexible retaining structures used to provide a temporary construction area for construction of structures. Sheet piles are made of timber, steel, or sometimes reinforced concrete. Timber sheet piles were used in the past but their reuse is limited for temporary structures up to shallow depth. For all important structures and for depth > 3 m, steel sheet piles are more commonly used. The advantages of steel sheet piles are that they are water tight and can be removed and reused after the construction of the structures is completed. Reinforced cement concrete (RCC) sheet piles may be sometimes used in fine sand or soft clays. RCC piles may get damaged or broken under driving stresses in stiff soils.

Sheet piles are installed by first driving the steel or timber sheets into the soil. The soil on the front side is then dredged (removed) out. The level up to which the soil is dredged out on the front side of the sheet pile is known as dredge level. Individual steel sheets are joined by ball-and-socket joints to obtain the required length of sheet piles.

Difference between a Sheet Pile and a Retaining Wall:

A conventional RCC retaining wall derives its support mainly from the weight of the wall as well as from the weight of the soil retained above the heel slab. The depth of foundation is usually small, and passive resistance of the soil is usually neglected in the design. In the case of sheet piles, lateral support is mainly derived from the passive resistance of the soil below the dredge level. Hence, the depth of foundation (embedment) is large compared with that in a retaining wall. The thickness of sheet piles is very small compared with the depth and length of a wall. Hence, the weight of a sheet pile is very small and is usually ignored in the design.

ADVERTISEMENTS:

The soil on the back of the sheet pile is usually removed and backfilled with a cohesionless soil. Hence, the backfill for all sheet piles is a cohesionless soil. However, the soil below the dredge level may be either a cohesionless soil or a cohesive soil, depending on the soil profile at the site of construction.

Sheet piles having water on the front side used in dock and harbor structures to facilitate berthing of vessels (ships) are known as bulk heads. When sheet piles are used for construction of structures in coastal regions on the sea shore, water will be there up to some depth on both sides of the sheet pile.

Standard sections of steel sheet piles as suggested by US Steel (1984) are shown in Table 16.3.

There are two types of sheet piles:

i. Cantilever sheet pile.

ii. Anchored sheet pile.

The cantilever sheet pile derives its support from the embedment into the underlying soil below the dredge level, as shown in Fig. 16.11. Hence, the design of cantilever sheet piles involves determination of the depth of embedment of the sheet pile to ensure its lateral stability.

In the case of anchored sheet piles, additional lateral support is provided by means of anchor rods fixed to the sheet pile near the top and anchored suitably, as shown in Fig. 16.12. The lateral stability of anchored sheet piles is derived both from the embedment into the soil below the dredge level as well as by the support provided by the anchor or tie rod.

The design of anchored sheet piles involves determination of the depth of embedment as well as the force (tension) in the anchor rod. The depth of embedment depends on the depth of soil to be retained above the dredge level and the type and properties of the backfill and the underlying soil below the dredge level.

The anchorage is provided by means of an anchor or tieback at or near the head of the wall. More than one set of anchors or tiebacks can be used. Provision of anchorage increases wall stability and enables taller walls to be built. In the case of cantilever sheet pile walls, if the deflection at the top point of the sheet pile wall is very large, then settlement of soil takes place at the top just behind the sheet pile wall. The anchors are provided to reduce excessive deflections.

The following are the different types of anchorages used for anchored sheet piles:

i. Tie rods with deadman.

ii. Tie rods with anchor walls.

iii. Tie rods with grout anchor.

iv. Tie rods with bearing piles.

v. Anchorage with tension piles.

The different types of anchorages provided to sheet pile walls are shown in Fig. 16.13.

Type # 7. Miscellaneous Types of Retaining Structures:

Diaphragm walls are commonly used in congested areas for retention systems and permanent foundation walls. They can be installed in close proximity to existing structures, with minimal loss of support to existing foundations. In addition, construction dewatering is not required, so there is no associated subsidence. Diaphragm walls have also been used as groundwater barriers below dams.

Diaphragm walls are constructed by the slurry trench technique, which involves excavating a narrow trench that is kept full of bentonite slurry. The slurry exerts hydraulic pressure against the trench walls and acts as shoring to prevent collapse. Slurry trench excavations can be performed in all types of soil, even below the groundwater table.

Cast-in-place diaphragm walls are usually excavated under bentonite slurry. The construction sequence usually begins with the excavation of discontinuous primary panels. Stop-end pipes are placed vertically in each end of the primary panels to form joints for adjacent secondary panels. Panels are usually 2.4- to 6-m long, with widths varying from 0.6 to 1.5 m.

Once the excavation of a panel is complete, a steel reinforcement cage is placed in the center of the panel. Concrete is then poured in one continuous operation, through one or several tremie pipes that extend to the bottom of the trench. The tremie pipes are extracted as the concrete rises in the trench. However, the discharge of the tremie pipe always remains embedded in the fresh concrete.

The slurry, which is displaced by the concrete, is saved and reused for subsequent panel excavations. When the concrete sets, the end pipes are withdrawn. Similarly, secondary panels are constructed between the primary panels, and the process continues to create a continuous wall. The finished walls may require cantilever or require anchors or props for lateral support.

The gabions are steel wire cages filled with quarry run or river run stones available at the site of erection. Gabion walls are constructed by stacking and tying wire cages filled with trap rock or native stone on top of one another. Cages are stacked to construct structures of great durability and flexibility. Each unit is securely connected to each adjacent cage during construction. Gabions are used to retain soil up to small heights of 3-4 m.

Gabions are particularly used, where the retaining wall needs to allow high amounts of water to pass through it, such as hydraulic structures in river training works and in protection works for roads and land reclamation. It is important to use a filter fabric with the gabion to keep the adjacent soil from flowing into or through the cages along with the water.

Gabions form flexible structures that can withstand the movement of the ground without inordinate structure deformations. This attribute enables the gabion structure to be built with minimum foundation preparation. Gabion structures behave as perforated barriers, allowing water to gradually pass through them. This is a valuable characteristic as hydrostatic pressure never builds up behind or under the structure to cause failure. Vegetation can be re-established around the gabions and can soften the visible edges, allowing them to blend into the surrounding landscape. For local roads, they are a preferred low-cost retaining structure.

Gabion structures are regarded as permanent. In the early stages after installation, siltation takes place between the stone fill, promoting vegetation and adding to the permanency of the structure. In view of the environmentally friendly nature of the gabion construction as compared with concrete, gabions are becoming more popular in engineering works in river embankments which demand a natural-looking environment with growth of vegetation and potential for ecological lives.

Gabion aprons are commonly used to protect the toe of a gabion retaining wall structure from scour that could cause undermining in channel works applications. A gabion apron will require minimal excavation and grade work. Generally, a gabion apron and a gabion block are placed directly on the ground utilizing a geotextile filter fabric between the gabions and soil interface to prevent leaching of soils underneath the gabions.

The following is the procedure for installation of gabion walls:

a. For ease of handling and shipping, the gabions are bundled and folded flat. Open the bundle and unfold each unit.

b. Lift the sides, the ends, and the diaphragms of each unit into vertical position.

c. Attach the sides of the four corners together with the locking wire fastener or tying wire and the diaphragms to the front and back of the gabion.

d. Assemble the empty gabion baskets individually and place them on the approved surface.

e. Connect all adjoining empty gabion units along the perimeter of their contact surfaces to obtain a monolithic structure.

f. Place a well-graded stone into the gabion units in 300-mm lifts. The fill layer should never be more than 300-mm higher than any adjoining cell.

g. Close the lids of the gabion units and connect with wire as in the case of sides along all edges, ends, and diaphragms.

The base layer of gabions should be placed below the expected maximum scour depth or the toe can be protected with gabion mattresses.

Gabion baskets placed on the outside of the river bend to prevent river bank erosion during floods. Gabions can flex to ground movement, dissipate energy from flowing water, and drain freely. Their strength and effectiveness may increase with time, as silt and vegetation fill the voids and reinforce the structure.

Multi-tiered gabion walls can be installed using galvanized gabions as well as geogrids and geotextiles, creating a “MSE wall” (mechanically stabilized earth). Gabion bridges have been built in the African Congo as a low-cost alternative to concrete culverts.

iii. Crib Walls:

Crib walls are one of the oldest gravity wall systems, composed of a series of stacked members, creating hollow cells filled with soil or rock. Crib walls are constructed of interlocking prefabricated units of reinforced or unrein-forced concrete or timber elements. Each crib is composed of longitudinal and transverse members. Each unit is filled with free draining material. Crib wall systems can be aesthetically pleasing because they can accommodate complex curvature and be planted with climbing vines, giving them a much “softer” appearance than more conventional support systems.

Crib walls have been made of various materials, including wood, concrete, and even plastic. Cribs are made of interlocking headers and stretchers that are stacked like the walls of a log cabin. Heavy construction equipment is required to lay the courses, possibly impacting sensitive areas. Cribs can be used for moderate heights of 4-6 m. The timber crib wall at South Benwell is one of the largest crib walls.